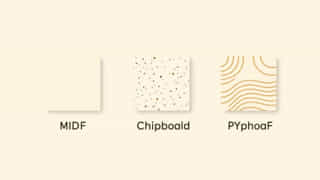

Mdf Vs Chipboard Vs Plywood

When it comes to choosing materials for furniture, cabinetry, or construction projects, the decision often comes down to MDF, chipboard, or plywood. Each material offers unique benefits and drawbacks, depending on your specific needs, budget, and desired finish. Understanding the differences between MDF vs chipboard vs plywood is essential to ensure a durable, cost-effective, and visually appealing result. While all three are engineered wood products made using wood remnants, they differ significantly in terms of strength, appearance, workability, and moisture resistance.

Material Composition and Manufacturing Process

What is MDF?

MDF, or Medium Density Fiberboard, is made by breaking down hardwood or softwood residuals into wood fibers. These fibers are then combined with wax and resin binders under high temperature and pressure to form dense, flat panels. MDF is known for its smooth surface and consistent density, which makes it ideal for painting and carving. It’s widely used in interior applications where aesthetics matter.

What is Chipboard?

Chipboard, also called ptopic board, is produced by compressing wood chips, sawdust, and shavings with a resin binder. It is generally denser and cheaper than solid wood but has less strength and moisture resistance. Its coarse texture makes it less attractive in its raw form, which is why it’s often laminated or veneered. Chipboard is popular in flat-pack furniture and budget-conscious projects.

What is Plywood?

Plywood is made by bonding multiple layers of thin wood veneers, with each layer’s grain placed perpendicular to the previous one. This cross-grain technique enhances the material’s strength and resistance to warping. Plywood is available in various grades and thicknesses, including options for indoor and outdoor use. It is considered one of the most durable and versatile engineered wood products.

Strength and Durability Comparison

MDF Strength and Weaknesses

MDF has a uniform structure that provides decent strength for interior projects. However, it is not as durable as plywood and can sag under heavy weight. It is also prone to swelling and warping if exposed to moisture, making it unsuitable for wet environments unless a moisture-resistant grade is used.

Chipboard Limitations

Chipboard is the weakest among the three materials. It is highly susceptible to moisture damage, and its edges can crumble when cut. It is not suitable for load-bearing structures or high-stress areas. Despite this, it serves well in lightweight applications like interior shelving and furniture panels when cost is a major factor.

Plywood Strength and Stability

Plywood is the strongest and most stable option due to its layered structure. It resists warping, cracking, and shrinking better than MDF or chipboard. It’s capable of supporting heavier loads and performs well in environments with varying humidity. Plywood is often used in flooring, roofing, and wall sheathing where strength is critical.

Workability and Finishing Options

Working with MDF

MDF is easy to machine, cut, and shape. It doesn’t splinter and provides a smooth surface for painting and laminating. However, it generates a lot of fine dust during cutting, which requires proper protection and dust control. Screw holding capacity is moderate, and pre-drilling is recommended to avoid splitting.

Handling Chipboard

Chipboard is also easy to cut but tends to chip or crumble at the edges. It doesn’t hold screws as well as plywood or MDF and is more fragile under stress. Most chipboard needs to be laminated or veneered for an attractive appearance. Careful handling is needed to avoid surface damage.

Plywood Machining and Finishing

While plywood is more challenging to cut due to its layered grain, it provides strong screw-holding capability and structural integrity. Plywood may splinter at the edges during cutting, so sharp tools and precise methods are required. Higher-grade plywood can be stained or varnished for a premium wood finish, while lower grades are ideal for concealed structural work.

Applications and Use Cases

Common Uses for MDF

- Interior furniture and cabinets

- Decorative moldings and trims

- Wall paneling and wainscoting

- Painted furniture pieces

Where Chipboard Works Best

- Economical flat-pack furniture

- Closets and wardrobes

- Underlayment for countertops

- Temporary or low-cost structures

Ideal Uses for Plywood

- Construction projects (flooring, roofing, wall sheathing)

- Outdoor furniture (using exterior-grade plywood)

- Cabinet carcasses and drawer boxes

- Furniture frames and substructures

Moisture Resistance and Environmental Exposure

MDF and Moisture

MDF absorbs water quickly and can swell or deteriorate if not sealed properly. There are moisture-resistant MDF products available, often used in kitchens and bathrooms, but they still don’t match the performance of plywood in wet conditions.

Chipboard’s Reaction to Moisture

Chipboard is highly sensitive to water and can disintegrate when wet. It should be used only in dry, interior environments. Laminated chipboard offers slightly better moisture resistance, but not enough for high-humidity areas.

Plywood’s Superior Resistance

Plywood is naturally more resistant to moisture, especially when using exterior-grade or marine-grade variants. It is suitable for both indoor and outdoor use, offering reliable performance in humid conditions or areas prone to spills.

Cost Considerations

Budget and Value

Chipboard is usually the cheapest option, making it attractive for cost-conscious buyers. MDF is moderately priced and offers better finish options. Plywood is the most expensive, particularly high-grade or exterior types, but offers long-term value due to its durability and strength.

Long-Term Investment

If your project demands durability and will be exposed to stress or moisture, plywood is the better long-term investment. For indoor projects that require smooth finishes and detailed work, MDF offers excellent value. Chipboard remains the best option when affordability is the top priority, and aesthetics or longevity are less important.

Pros and Cons at a Glance

MDF

- Pros: Smooth surface, easy to paint, good for detailed work

- Cons: Susceptible to moisture, average screw holding, produces dust when cut

Chipboard

- Pros: Low cost, lightweight, easy to machine

- Cons: Weak structure, poor moisture resistance, unattractive raw appearance

Plywood

- Pros: High strength, moisture resistant, versatile

- Cons: More expensive, can splinter, less smooth than MDF

Choosing the Right Material

Project Goals Matter

Selecting between MDF vs chipboard vs plywood ultimately depends on your project’s requirements. For painted surfaces or decorative details, MDF stands out. For budget builds where appearance is secondary, chipboard is sufficient. For structural strength and durability, plywood is unmatched.

Balancing Price and Performance

If you can spend a bit more for quality, plywood offers excellent return on investment. For medium-grade performance at a reasonable price, MDF is a strong candidate. For temporary, indoor, or low-cost needs, chipboard remains a practical solution.

Choosing between MDF, chipboard, and plywood requires understanding how each material behaves under different conditions. MDF is best for smooth finishes and decorative work, chipboard excels in affordability, and plywood is the strongest and most moisture-resistant. Knowing where and how you intend to use these materials helps ensure long-lasting results that meet both functional and visual goals. By evaluating the characteristics, strengths, and cost of each type, you can make a well-informed decision suited to your specific woodworking or construction needs.

#kebawah#